The Oxide Badge

The Oxide Badge is an original feature of Mixup. It was developed to give a quick impression of the oxides that make up a glaze.

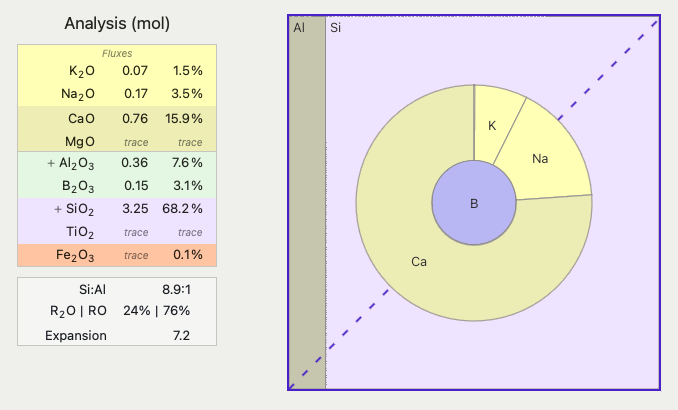

The Oxide Badge shows a mix's oxides in graphical form. Consider the following analysis and Oxide Badge:

The badge shows in graphical form the same numbers as are in the analysis. The area of any oxide on the badge corresponds to its relative value. The badge has two parts:

- The flux circle

- The non-flux field

The flux circle contains all of the fluxes in the glaze, with the addition of boron oxide in the center. The fluxes are grouped as:

- Alkali Fluxes: Li2O, Na2O, K2O

- Alkaline Earth Fluxes: MgO, CaO, SrO, BaO

- Metallic Fluxes: ZnO, PbO

In a unity analysis the fluxes total to one, so the flux circle shows the flux oxides in a pie chart, adding up to one complete circle. You can see in the example above that the similarly colored alkali fluxes are about a quarter of the total fluxes.

The flux circle should be viewed as being in front of the non-flux field. Aside from boron oxide the flux circle is proportionally one in size. In the above case the unity value of silica is 3.25, and the silica rectangle behind the flux circle is 3.25 times the size of the fluxes in the flux circle. Since the value of boron is 0.15 the total proportional area of the flux circle is 1.15.

The important thing to remember is that the amount of an oxide in the glaze is proportional to the area in the badge, and that the fluxes are displayed in front of the other oxides in a circle.

Oxides can have more than one role in a glaze, and that is especially true of boron oxide. Boron is both a glass former and lowers the melting temperature of a glaze. Most potters think of it having the role of a flux, so it is included in the flux circle.

For simplicity the oxygen part of the oxide is not displayed.

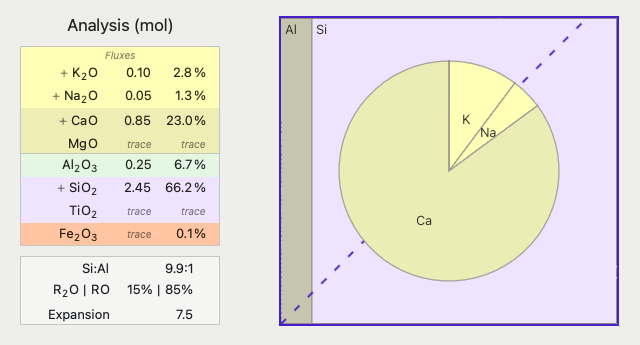

The dashed diagonal line represents a 9:1 proportion of silica to alumina. If the non-flux field is wider that the diagonal the glaze has a higher silica to alumina ratio, or in other words is has surplus silica, as in this glaze:

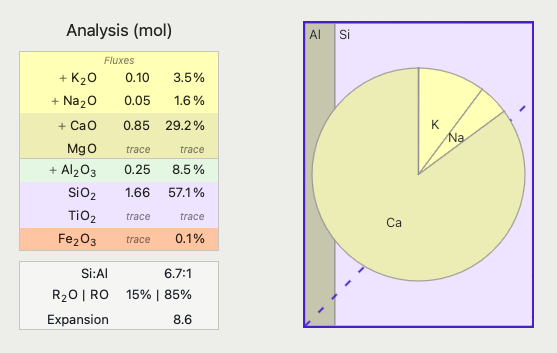

If the non-flux field is narrower than the diagonal then the glaze is relatively short of silica:

Transparent glazes are often found near a 9:1 silica to alumina ratio, but there are many interesting glazes that are comparatively long or short on silica. Like all things in glaze chemistry you should take the 9:1 ratio as only a very rough guideline.

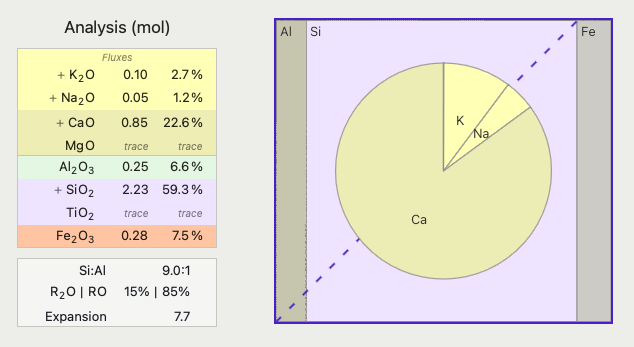

Non-flux oxides aside from alumina and silica are displayed on the right side of the non-flux field. For example, this glaze has a lot of iron:

More details on the Oxide Badge can be found in this white paper.